Welcome to The Official Website of GM Cricket

Blending over 130 years of expertise with the love of the game.

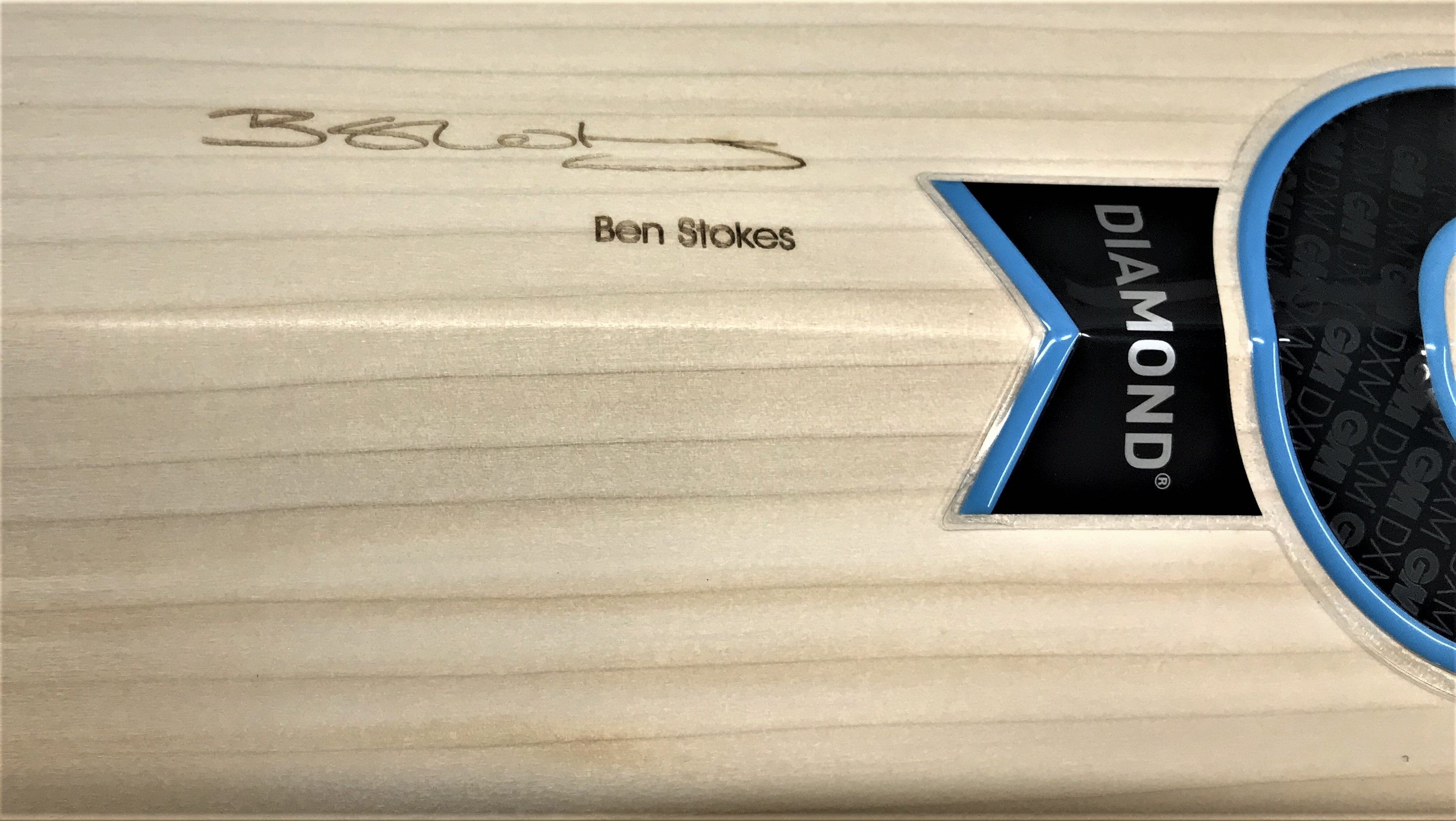

All GM DXM English Willow bats are made by our own staff in our own factory in Nottingham, England. Gunn & Moore make the finest cricket bats in the World. Pick up a GM cricket bat and you will instantly know from the balance, finish and ultra high quality presentation that this is English Design and Craftsmanship at its very finest.

Why GM? Well watch the video - click on It all comes down to choice